The Advance Feature Gradiometer scanner, with its exceptional design and highly advanced programming, has transformed into a high-quality, professional, and beautiful product. The high-quality assembly and the use of top-notch equipment, along with an aluminum body, have left no room for competition for both domestic and even similar foreign products! For ease of use and transport, this product does not have a separate control unit but is equipped with its own driver through complex engineering and unique design thinking. Unlike its foreign counterparts, the Advance Feature is equipped with a beautifully designed and professional display screen, offering a wide range of options and tools tailored to the needs of Iranian users. This beautiful product is available with FL1-100, FLC-100, and FLC3-70 sensors from Stefan Mayer Germany, in two versions: single-axis and total field.

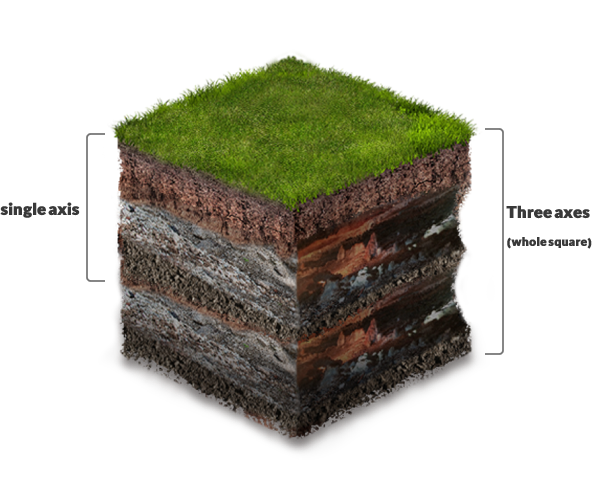

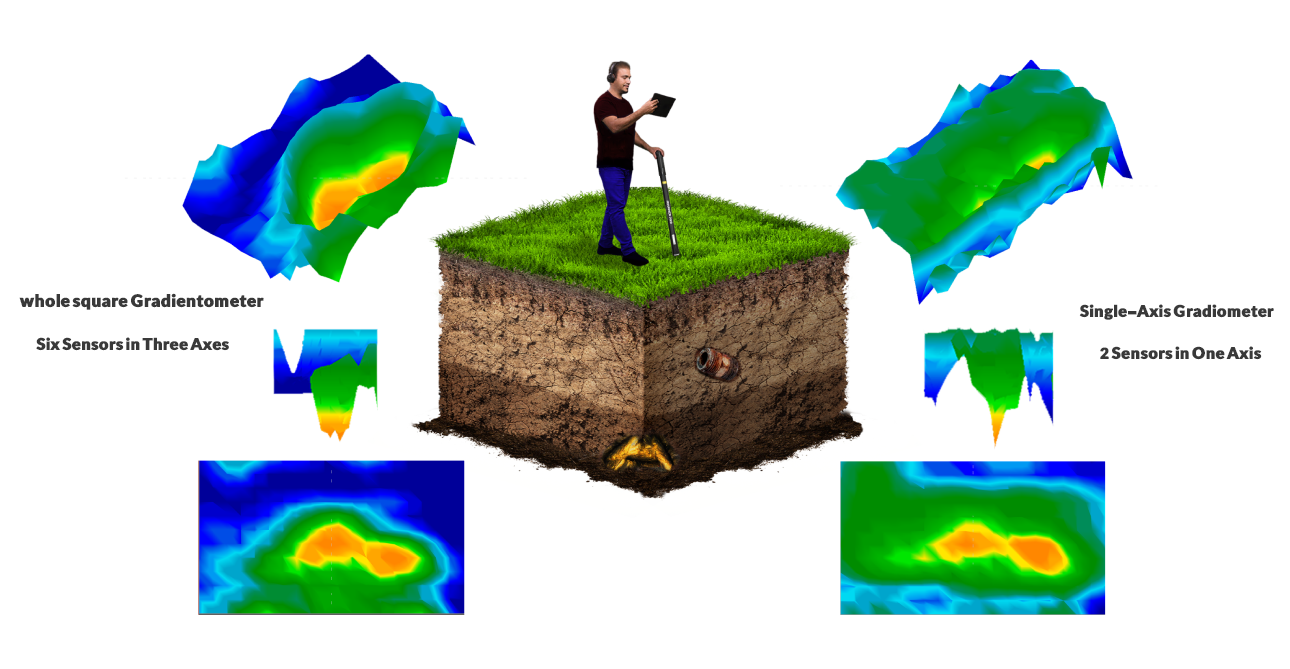

Total field systems are suitable for deeper exploration and are used for larger targets. Unlike single-axis systems, they have more capabilities in terms of eliminating noise and false targets, detecting ferromagnetic metals in any orientation at depth, and recording two metals or two closely spaced objects. In fact, total field systems provide clearer imaging of deep targets while single-axis systems excel in detecting shallow targets rather than deep ones.

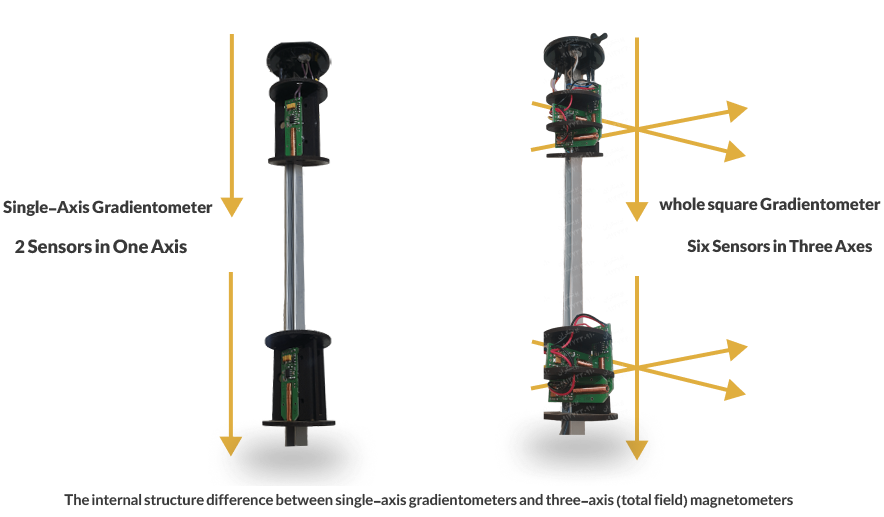

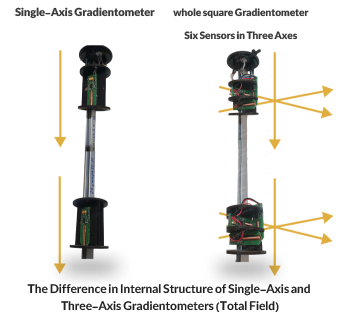

Single-axis gradientometers, like many common products worldwide, consist of two sensors, one placed at the top and the other at the bottom of the probe. Since both sensors are aligned along the same axis, they are referred to as single-axis. However, three-axis gradientometers, also known as total field gradientometers, differ from single-axis models. They employ six sensors, allowing them to measure variations in the Earth's magnetic field in three dimensions, providing a more comprehensive understanding of the magnetic environment

Real-time display of the number of lines and pulses captured during scanning.

Capable of various scanning methods including automatic, manual, graphical imaging, and audio

Smart removal of salts and particles for displaying real targets and easier analysis

To maintain the Super Sensor completely vertical by the operator in order to assist in reducing operator errors and obtaining precise scans

Magnetic field reading down to below 1 nanotesla with adjustable settings

Wireless Communication Between Super Sensor and PC Software

The ability to adjust the time interval between measurement steps in automatic mode

Audio scanning with graphic display on the LCD (similar to a metal detector with pinpoint and pointer capabilities without the need for a laptop)

Capability to store data in internal memory

To adhere to the Warm-Up principles and create temperature balance between the sensor and the ambient temperature

The ability to adjust resolution from 12 bits to 18 bits while maintaining stability

Pooyeshgaran Company proudly stands as the only company in the world that provides users with an index of the sensors used in its products for the purpose of trust-building